What Is Blanchard Grinding? Everything You Need to Know

This guide contains everything you need to know about Blanchard grinding.

So whether you have hands-on experience at the Blanchard grinder, or if you are new to the Blanchard grinding process, this article has something for you.

Here’s what we’ll cover:

- What Blanchard grinding is

- How Blanchard grinding works

- Benefits of Blanchard grinding

- Downsides of Blanchard grinding

- What you can Blanchard grind

- The accuracy of Blanchard grinding

- The flatness of Blanchard grinding

- Where Blanchard grinding comes from

- Differences between Blanchard and precision grinding

- How much Blanchard grinding costs

So let’s get the grinder buzzing and get down to work.

Do you need Blanchard grinding services? Contact our team at Ephrata Precision parts to get started!

What is Blanchard Grinding?

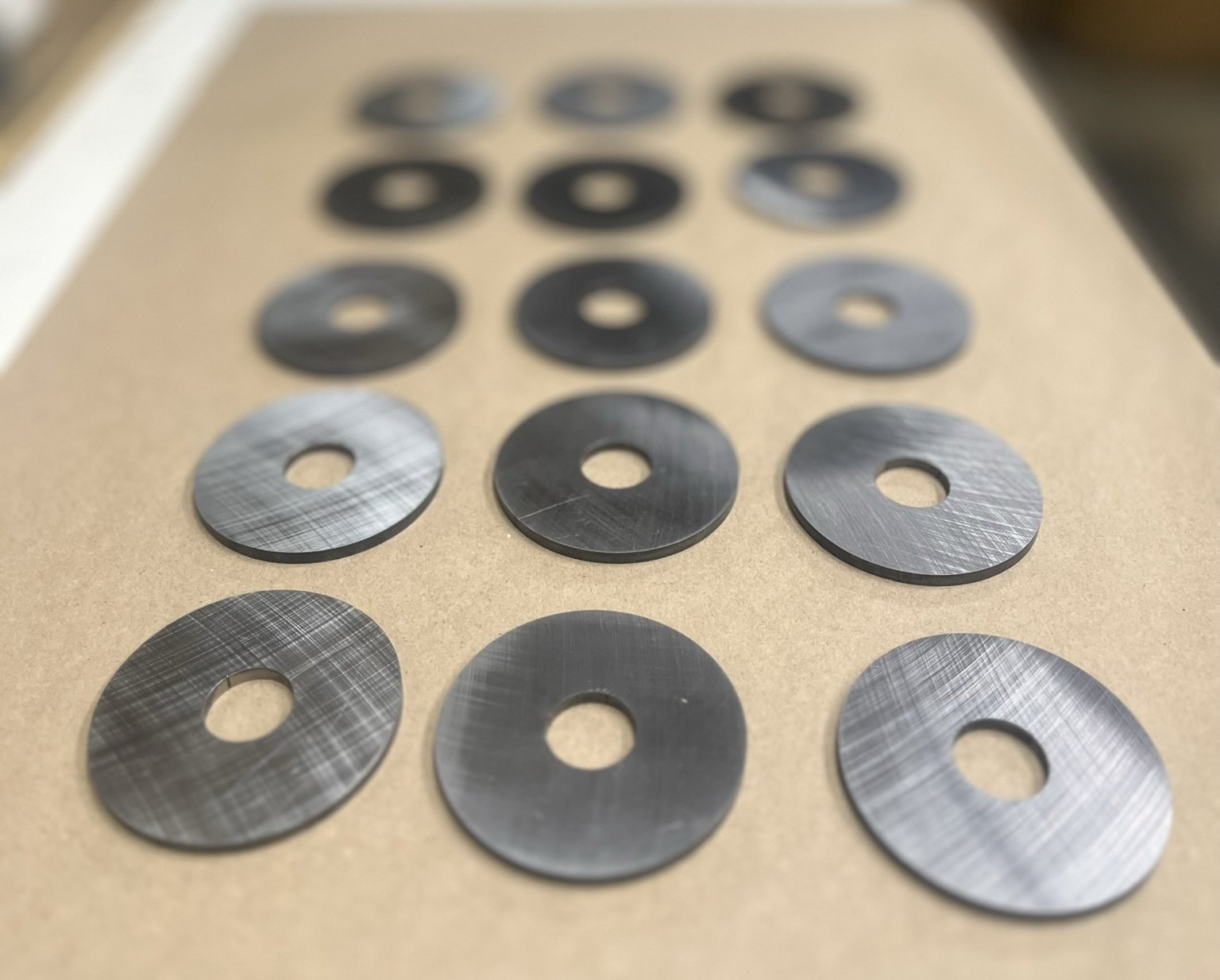

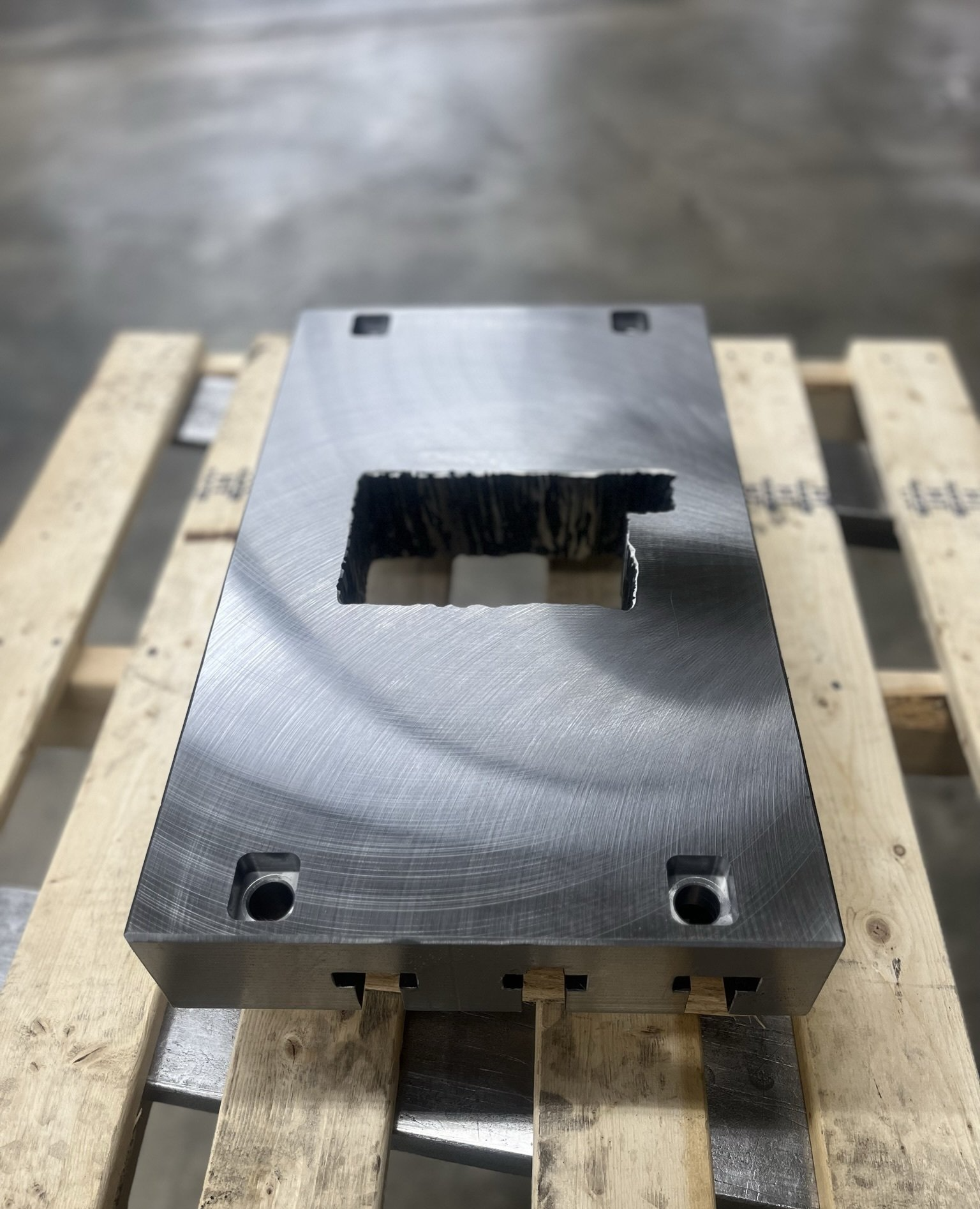

Blanchard grinding is a type of rotary surface grinding. The Blanchard grinder can remove large amounts of material from a workpiece, making it ideal for quickly finishing surfaces. This efficient method gets its name from the company that originally developed and patented the machine design, the Blanchard Machine Company. It is best suited for single-sided or double-sided grinding of parts with flat surfaces.

How does Blanchard grinding work?

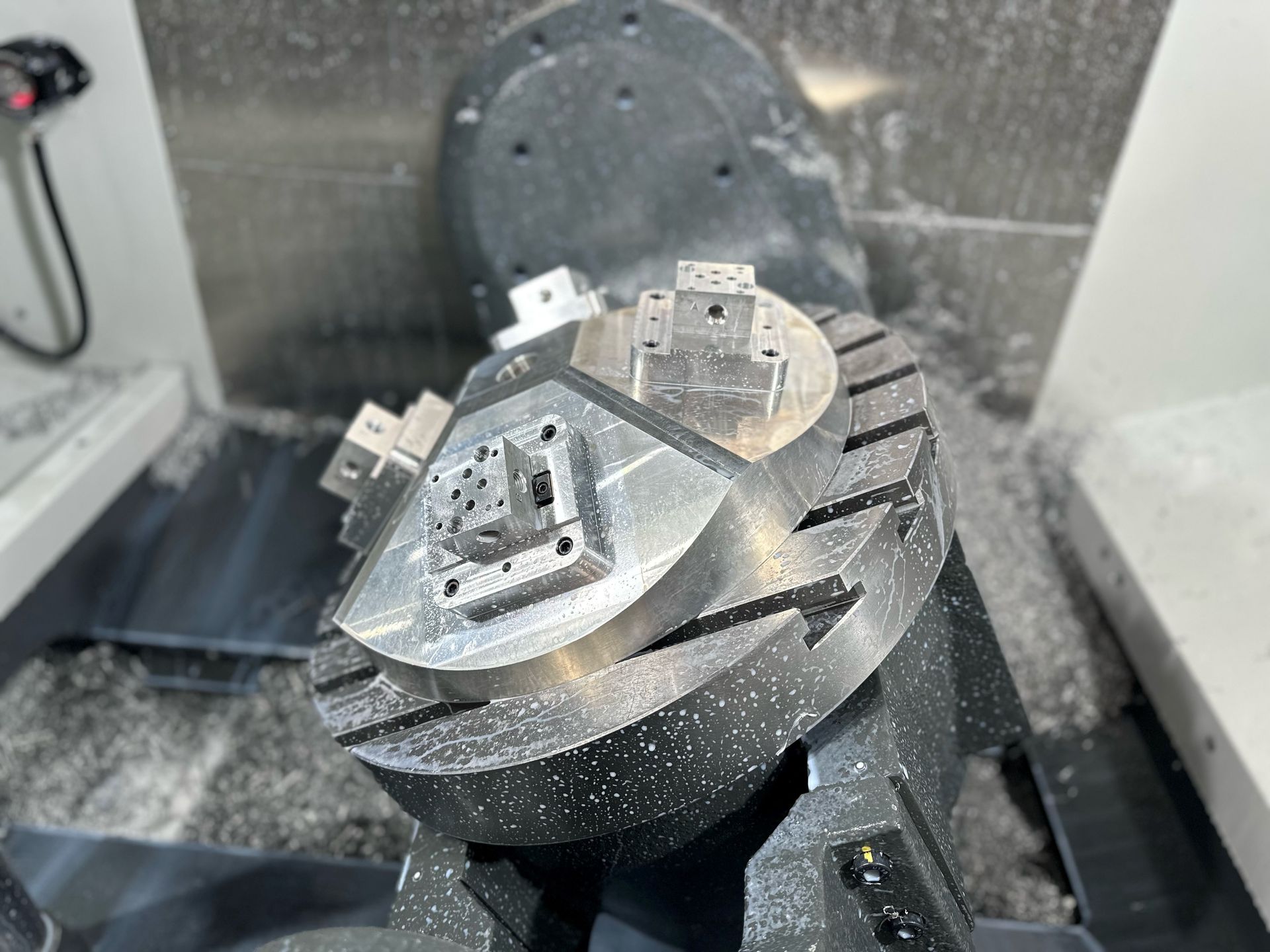

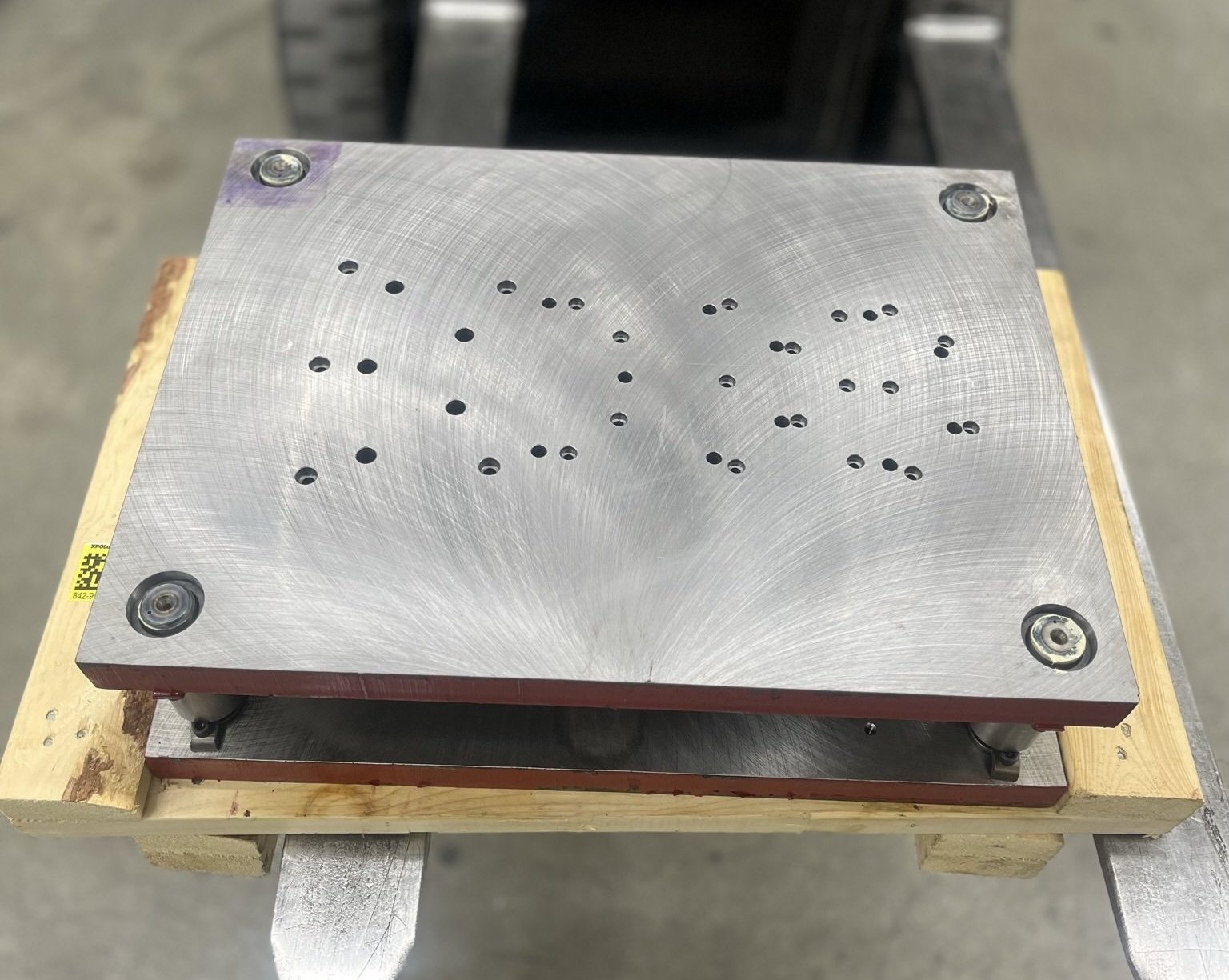

The grinding stones are mounted on a vertical spindle and creates a cross-hatch pattern while the part is rotated on a magnetic chuck. This grinding method is used to remove stock from one side of a part. Blanchard grinding can produce a very fine finish with little or no coarseness on the surface of the part.

What are the benefits of Blanchard grinding?

The main advantages of Blanchard grinding are high material removal rates and fast cycle times. It is also one of the most cost-effective types of precision grinding.

Are there any downsides to Blanchard grinding?

The main disadvantage is thermal damage to the workpiece, especially if not the work is not performed correctly or is rushed. When it comes to Blanchard grinding, you want to make sure you

entrust your work to the right people.

What can you Blanchard grind?

Blanchard grinding can be used on a variety of materials, including ferrous metals, non-ferrous metals and plastics. Examples of pieces that use Blanchard grinding are

- Tool and die

- Large stampings

- Castings

- And plate stock

Can you Blanchard grind aluminum?

Aluminum can be Blanchard ground, but it requires a fixture to be held in place on the magnetic chuck. For this reason, Blanchard grinding is not typically used on aluminum unless it is absolutely necessary.

Can you Blanchard grind stainless steel?

When grinding stainless steel, the metal workers must be careful not to overheat the metal, as this can cause damage to the material. Grinding stainless steel with a Blanchard grinder can provide a high-quality surface finish with minimal material removal. Certain grades of stainless steel will require fixturing similar to aluminum because of its lack of magnetism.

How accurate is Blanchard grinding?

Blanchard grinding is well suited for large-scale surface grinding, as well as for small parts that need to be held in place with a chuck during grinding. And, it can achieve very high levels of precision and accuracy, achieving tolerances of plus or minus 0.001 inches (0.0254 mm).

However, the process is not without its challenges. In particular, the large grinding wheels used in Blanchard grinding can cause vibration and noise, making the process less than ideal for some applications. Nevertheless, when used properly, Blanchard grinding can be an extremely effective material removal technique.

What tolerance of flatness can you achieve with Blanchard grinding?

Typical flatness easily achievable on a Blanchard grinder would be around ±.001 (0.0254mm) or better.

Who invented the Blanchard grinder?

In 1909, Winslow Blanchard of Blanchard Machine Company in Cambridge, Massechussettes, assigned one of his inventors to concoct the Blanchard Grinder. Henry K. Spencer, who had just graduated from MIT, developed the vertical rotary surface grinder within six months.

The original machine started off small in diameter, but as attention grew, grinding machines became more in demand, evolving over the past 100 years. Now, Blanchard grinders are much larger than they used to be, but still deliver that smooth surface finish many machinists and companies were after in 1909.

What is the difference between Blanchard and surface/cylindrical grinding?

If you are well versed in the industry, you will know that there are many different types of grinding methods. Some of the most popular are rotary Blanchard grinding and surface/cylindrical grinding. So what are the differences in methods of grinding?

Blanchard Grinding

As we have established, Blanchard Grinding is for large flat surface areas. Blanchard Grinding is considered to have more aesthetic appeal as well, leaving a surface finish of 63 Ra or less.

Surface/Cylindrical Grinding

Surface/Cylindrical grinding is geared towards high precision tolerance and finish work. It can achieve a surface finish of 8 Ra or less, and tolerances of ±.XXXX or better.

- Cylindrical grinding — used for round objects

- Surface grinding — an abrasive wheel rotates at a high speed to grind a flat surface.

How much does Blanchard Grinding cost?

The cost of Blanchard Grinding typically depends on the material being ground, surface area size, and material thickness. If you are looking for a precise quote on a particular project, we would be happy to give you an estimate. So

contact us today for your free quote!

Blanchard Grinding is an essential step in producing quality, large parts for a variety of industries, and it’s something that we specialize in here at Ephrata Precision Parts. If you need help getting started with Blanchard Grinding, or if you have any other questions about our services, don’t hesitate to contact us. We would be happy to discuss your needs and see how we can help you get the results you need.