What Is 5-Axis Machining? History, Process, Applications, and More

What Is 5-Axis Machining?

5-Axis machining, a method employed in CNC (Computer Numerical Control), operates by moving a part or cutting tool along five different axes simultaneously. This process allows for efficient machining of complex parts, reducing human error, and shortening lead times.

The cutting tool can approach the workpiece from any direction, offering flexibility and precision. This versatility makes 5-axis machining integral to industries requiring intricate detailing, such as aerospace.

History of 5-Axis Machining

The concept of 5-axis machining originated during the mid-20th century, when machine configurations evolved to increase efficiency and precision.

A 5-axis CNC machine works by simultaneously moving a part or cutting tool along five different axes. This enables the machining of complex parts in a single setup, reducing human error, and shortening lead times. The cutting tool can approach the workpiece from any direction, resulting in a highly precise finished product.

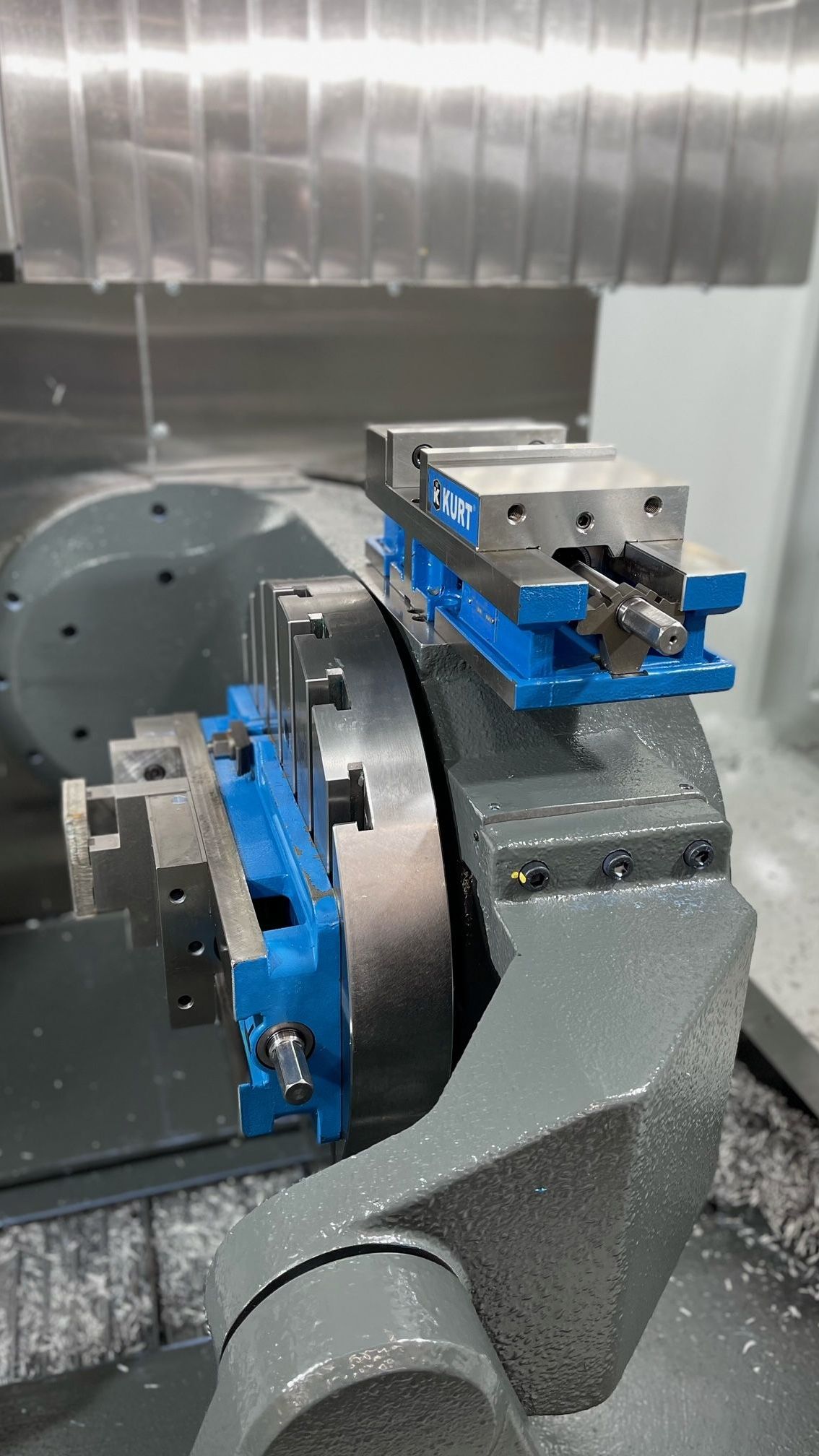

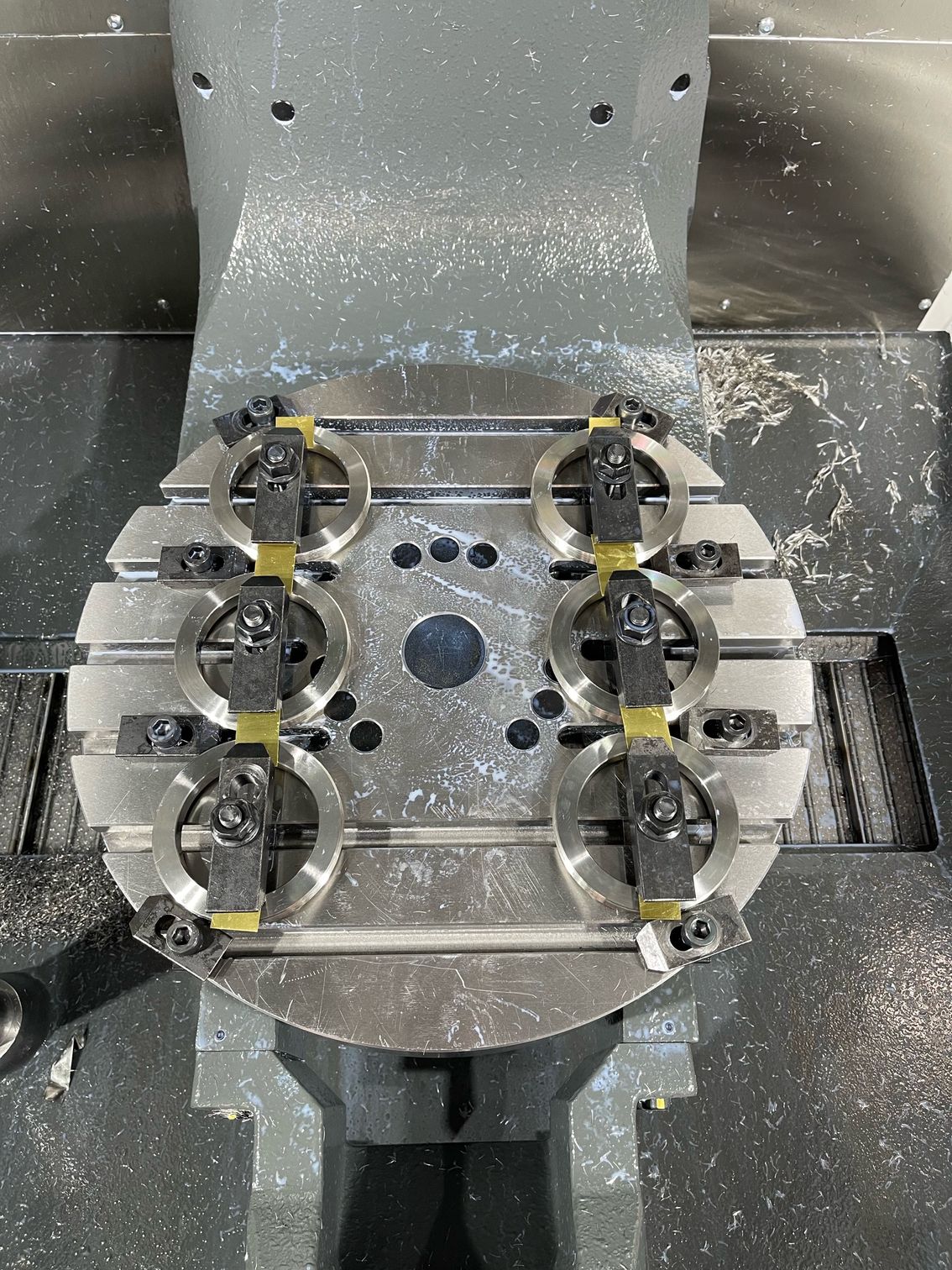

Components of a 5-Axis Machine

A 5-axis machine comprises several key components: the controller, drive system, feedback system, axis table, and spindle. The controller orchestrates the system, while the drive and feedback systems manage movement. The rotary axis table holds the workpiece, and the spindle manipulates the cutting tool.

5-Axis vs. 3-Axis CNC

5-axis CNC machines outperform their 3-axis counterparts in terms of versatility and precision. Unlike 3-axis machines, which limit movement to three directions, 5-axis machines maneuver along five different axes, enabling them to efficiently produce complex and intricate parts with shorter lead times and higher-quality surface finish.

How much does a 5-axis CNC machine cost?

A 5-axis machine comprises several key components: the controller, drive system, feedback system, axis table, and spindle. The controller orchestrates the system, while the drive and feedback systems manage movement. The rotary axis table holds the workpiece, and the spindle manipulates the cutting tool.

The cost of a 5-axis CNC machine varies widely based on its capabilities and specifications. Factors such as size, complexity, and brand significantly influence the price. However, despite the higher initial investment compared to 3-axis machines, 5-axis CNC machines often provide greater value in the long run due to their versatility, precision, and efficiency.

Benefits and Limitations of 5-Axis Machining

5-axis machining offers distinct advantages in precision and versatility, but it also presents challenges such as high costs and complex programming requirements. With that in mind we've highlighted a few more of the advantages and disadvantages for you here!

Advantages

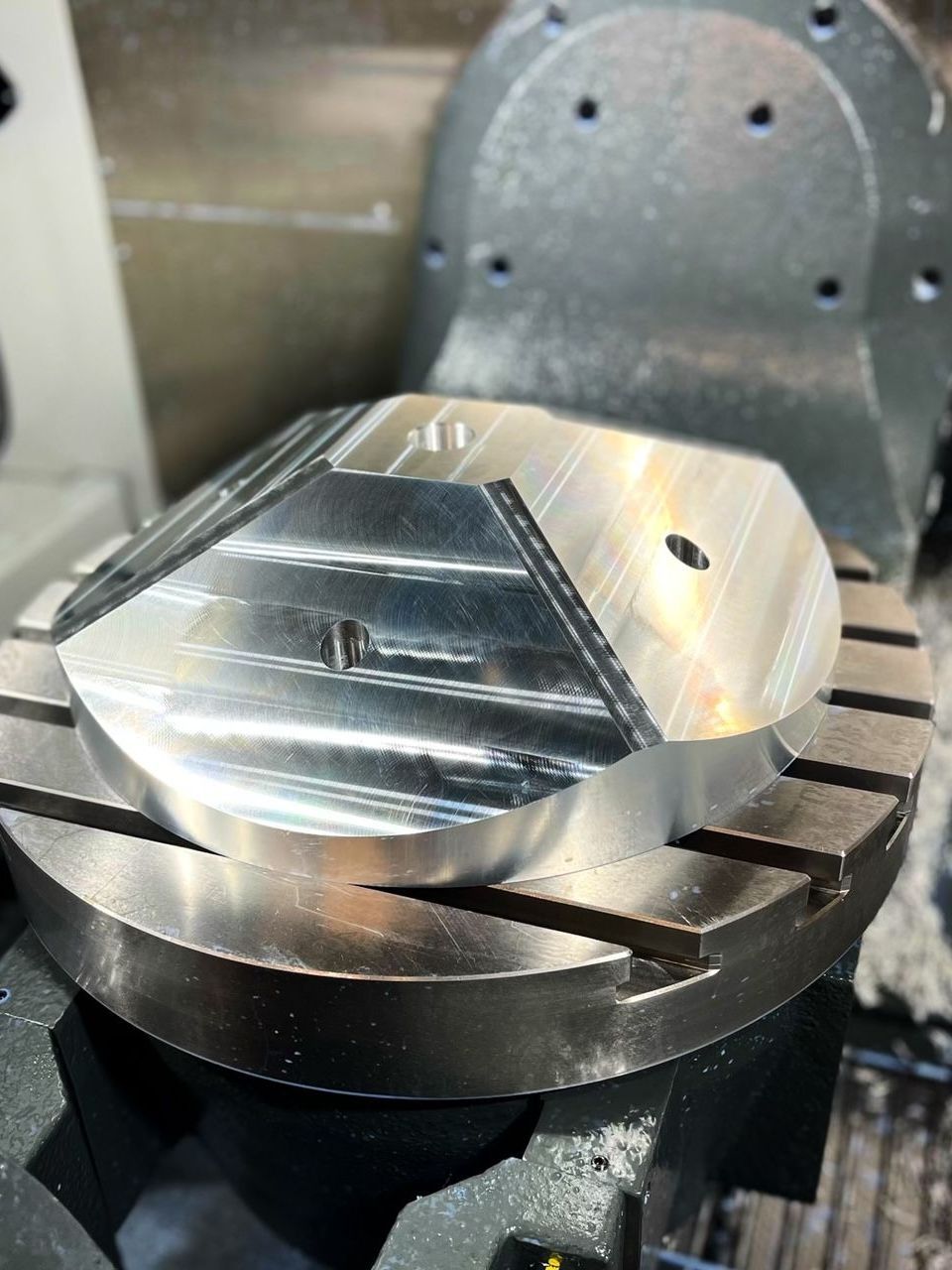

5-Axis machining bestows substantial benefits. It crafts complex parts swiftly, reducing the need for manual repositioning. This leads to shorter cutting times, lesser human error, and an improved surface finish. Its ability to handle heavier parts and eliminate multiple setups makes it a valuable asset in precision-oriented industries.

Drawbacks

Despite its numerous benefits, 5-axis machining also has its drawbacks. The complex programming requirements demand skilled operators and can lead to longer setup times. Furthermore, the initial investment for 5-axis machines is significantly higher compared to their 3-axis counterparts, potentially posing a barrier for smaller businesses.

Common Applications for 5-Axis Machining

5-Axis machining's versatility lies in its ability to produce complex parts with high precision, making it valuable across numerous industries, including aerospace, medical, and automotive.

Medical Device Manufacturing

5-Axis CNC machining plays a pivotal role in medical device manufacturing. It intricately crafts orthopedic implants, dental restorations, and surgical instruments with high precision. Furthermore, its versatility aids in producing intricate components of diagnostic equipment, enhancing the range and accuracy of medical diagnoses.

Automative Industry

5-Axis CNC machining significantly enhances automotive manufacturing processes. Its ability to produce complex, high-precision components streamlines production of engine parts and intricate car designs. By reducing error and boosting efficiency, it accelerates production cycles, fostering faster, more cost-effective car manufacturing.

Aerospace Industry

In the aerospace industry, 5-axis CNC machining is crucial for creating complex, high-precision parts such as turbine blades and aerostructures. With its superior precision and flexibility, it enables faster production cycles and ensures adherence to stringent aerospace manufacturing standards.

Mold and Die Making

In the field of mold and die making, 5-axis CNC machining excels. It accurately crafts detailed, complex molds and dies, drastically reducing manual labor and error. This technology also accelerates production cycles, delivering high-quality molds and dies at a faster pace.

Custom Prototyping

5-Axis CNC machining provides a valuable solution for custom prototyping. It crafts intricate prototype models swiftly and accurately, allowing for efficient design validation. This technology reduces production errors and accelerates the prototyping process, proving essential for innovative product development.logy was utilized primarily in the aerospace sector due to the need for complex, multidimensional components.

With advancements in CNC technology, 5-axis machining has expanded across multiple industries, including automotive and medical. For a detailed chronicle of the development of CNC technology, visit the MIT's Mechanical Engineering page. For an in-depth look at the incorporation of 5-axis machining in the aerospace industry, refer to the National Aeronautics and Space Administration (NASA) archives.

Expert 5-Axis Machining for Your Business

Ephrata Precision offers unparalleled expertise in 5-axis CNC machining, a technology essential for precision-oriented industries. Our 5-axis machining crafts complex parts swiftly and accurately, reducing human error, and delivering high-quality surface finishes.

Despite the initial higher investment, our machines provide greater value in the long run due to their versatility and efficiency. Whether it's medical device manufacturing, automotive, aerospace, mold making, or custom prototyping, Ephrata Precision is your trusted partner for sophisticated, high-precision machining solutions.